When Technology Fails: Strategies and Critical Skills for Coffee Roaster Operations

By Anne Cooper

We’ve all been there at some point in our roasting careers—we’re mid-roast and all of a sudden we lose all indications of our roast data because the computer has frozen. Or there’s a bad internet connection. Or maybe a low battery shuts down the laptop, an update starts loading at the wrong moment, we accidentally close the software app, there’s a loose cable connecting the phidget/data bridge, the probe is worn out or damaged, a rodent has eaten through the wiring (yes, it happens!). And that’s just to name a few.

Software companies have made amazing contributions to the industry, and with the broad adoption of this innovative technology, roasting software is becoming heavily relied upon in our everyday operations. What do we do when it fails mid-roast and we have no choice but to finish the roast on our own?

This article is a guide to what to focus on as roasters so we may stay sharp and alert and be able to troubleshoot our roasting and keep it on track in the event of software failing. What are the critical skills and strategies we can and should use in order to finish the roast and produce a desirable/sellable product without anyone knowing we lost our roast data/software mid-roast?

A blank screen with smudged lines—what a roaster would see in the event of a software failure. (Photo by Anne Cooper)

Ultimately, the core skill we need to connect with is our senses. “For me, it’s all about the senses at that point,” says roasting consultant Rob Hoos, “and knowing enough about the development time and end of roast temperature that I am aiming for to be able to finish the roast appropriately.”

To further define this reliance on our senses, we should remind ourselves of the fundamental concepts of roasting: What exactly is roasting, or what are we focusing on “sensing” while the beans are roasting?

A running joke in the industry, roasting is logically and essentially “turning beans brown.” During the browning process, we are focusing on the physical color changes of the beans and the timing of these key physical changes/events which, from tasting and personal/subjective anecdotal experience (not yet via science), we’ve discovered that making the beans physically change at certain times and rates in the roast has a massive influence on specific end flavors.

Often referred to as an old-school and subjective technique, noting the physical color changes of the bean throughout the roast is absolutely fundamental to the “how” of roasting. As roasters, we must bring to the roasting machine how we want to roast—how do you want to turn those beans brown, or at what rate do you want to see the beans go through the various stages of physical color change?

Not knowing how you want to roast is by far one of the most unsustainable practices in roasting. And, with a reliance on software and “lines on the screen,” it seems over time we have become dangerously obsessed, using wasteful practices in the pursuit of perfection, trying to achieve the perfect, straight look of the temperature lines in the software.

We’ve lost sense of the how because we were told it is old school and too subjective to watch and mark the coffee physically changing color during roasting. But the how of roasting is the main sense/technique that we dearly need to rely upon when those “perfect lines” disappear mid-roast!

Which raises the question—are we roasting the software or the beans in the roaster? Software is imperative for consistency in production environments, there is no doubt about that, but it can also make us lax toward the fundamental basics of trusting/building our senses during roasting, thus separating the roasters from the roaster operators.

There’s nothing wrong or old school about watching and smelling the coffee during a roast, identifying the physical color changes, and knowing what that means for your roasting and desired end flavors. Watching the coffee physically change color is roasting—just like cooking. Would you eat food from a chef who never looked at or smelled the food they were cooking? Absolutely not!

Coffee bean color changes during roasting. (Photo by Ed Kaufmann of InterAmerican Coffee)

Knowing how to watch the beans physically change during a roast is paramount to making good roasting decisions. It’s often a case of “when do we look at and interpret the software” versus “when do we look at the coffee beans cooking in the roaster” so we can then decide on what to do with the heat application and general operation of the roaster in order to produce a desired roast level and flavor outcome.

Practicing this is a core strategy and skill that will allow us to be more objective when calling/marking the physical color changes of the beans and thus allow us to be decisive and able to finish the roast in the event of software failing mid-roast.

No lines? No worries! Trust your sense of sight and smell.

So, along with using our senses to watch and smell the stages of green to brown, we also need to use our sense of time—marking and making key physical changes/cooking events occur at specific times, which is also enormously subjective to cultural palate and specific to a baseline product profile as defined by us and our customer base.

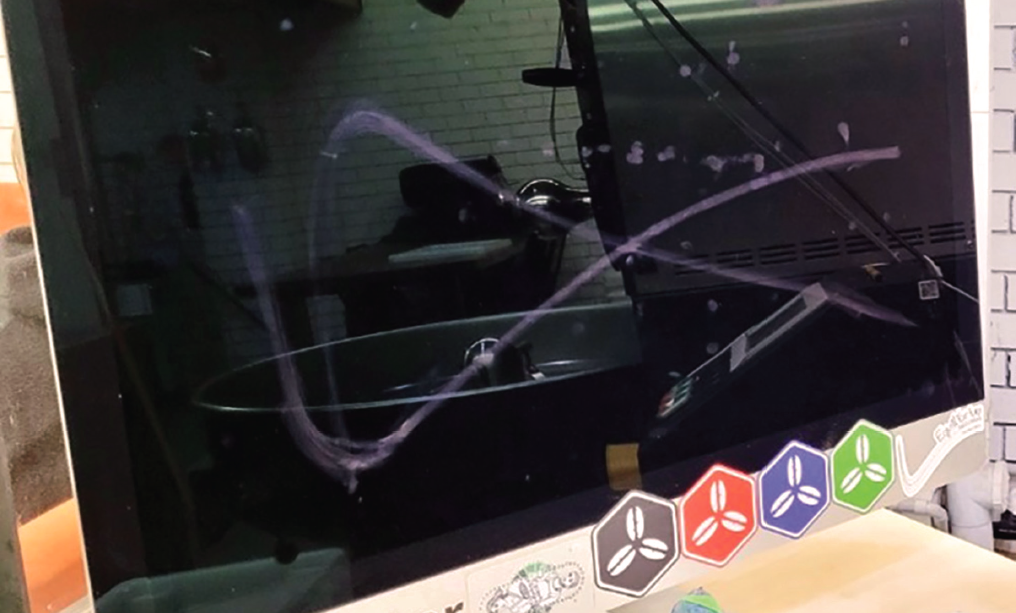

Referred to as phases, noting the desired target time (not percentages) for each of the three key phases in the roast profile (marking green to yellow, Maillard/yellow to first crack, and first crack to end) is something all roasters should do to clearly define a baseline profile for a specific product/roast level. These timed phases or the sequential progression of the beans cooking at a particular rate is far more informative to a baseline profile than software lines on the screen. (Yes, I did just say that!)

Knowing the target times for each of the three roasting phases allows a roaster operator to complete the process manually. (Photo by Anne Cooper)

So, in the event of a software failure, if we at least know the target times (not percentages) for each of the three phases, we will then be able to easily finish a roast by matching these phase times to the physical change/color and the desired end roast level.

An indication of time and the timing of the phases/stages of the physical changes of the bean (green to brown) is the one thing we can’t do without when roasting, and the one thing that can be transferred across different machines, as was proven through research published in the article titled “Can you Taste the Roasting System?” in the May/June 2019 issue of Roast.

Time was also the main thing all the roasters polled for this article said they relied on in the event of a software failure.

“I run a separate timer, and I can also rely on the difference between the temp on the roaster to the temp of the thermocouple connected to the software,” says coffee roaster Chris Priestly. “Also, time and appearance and smell. I know when it’s coming in to [first crack] smell-wise, and sight for green to yellow, and also roast depth after [first crack]. Time, smell and sight.”

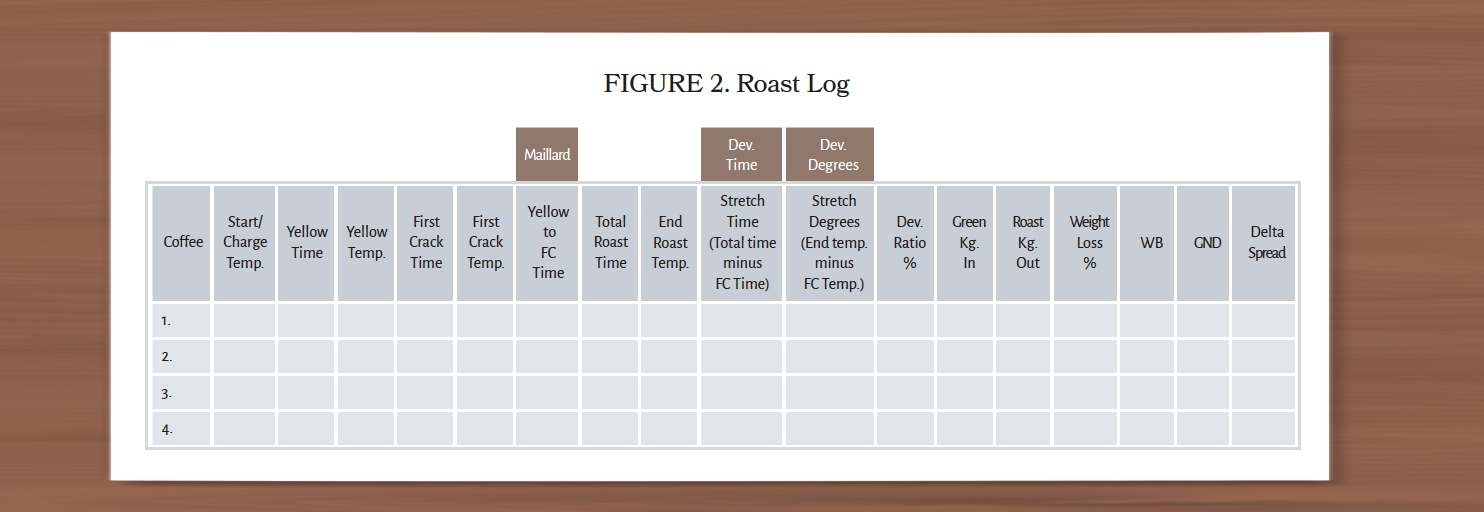

We practice and learn and show ourselves what flavors we like and don’t like through thorough recordkeeping in the form of a roast log, making sure we write down the right information, meaning anything related to time and the three key phases of the roast.

Having a roast log is the best way to help you define your profiles (and phases), so you can roast, record, taste and analyze to show yourself what you like and don’t like about a specific roast level/profile.

You will then know what to keep doing to create a baseline profile strategy.

The roast log will also help to show you how to best dial in a new coffee based on a past profile that worked for coffees with similar properties. It is always baffling to hear roasters say that they often head into a roast not knowing what to expect. You must head into a roast with a plan on how and when you want key events or phases to occur so you can make good decisions on how to apply heat to a specific coffee with specific properties to ensure that key physical events/phases happen on time.

Keeping a manual roast log helps a roaster develop and analyze roast profiles, and could be invaluable if software fails.

Heading into a roast with a baseline plan/strategy of the timing of key events/phases will basically force and teach you how to use/operate/adjust the roaster in order to make key events/phases happen at the right time. If you don’t show yourself how to do this with your recordkeeping, you will definitely be in a pickle in the event of software failing because you won’t know how to connect time to a key physical event to keep your roast in line to a desired outcome.

So, keeping a roast log is imperative to successful roasting and super helpful in situations when software fails.

Nick Rozental of Paddle Brew Coffee Lab in Indonesia had some great points on what he does with roast logs. “All our machines are set with data logging software, but we also keep old-school technology on hand as a backup,” he says. “Each roaster has a basic handheld timer, and we also keep the old-fashioned paper roast log or printed software log to monitor the roast, just in case s--- happens! All our roast profiles have a [paper] log attached to them as a reference that we use as a label pre- and post-roast as well as cupping. We love technology and cloud-based data, but nothing beats a visual label/log on a green or roasted bucket. This way we can keep running the roast based on time, and we can estimate the temperature and the next steps to take.”

Manual notes on a roasting machine control panel. (Photo by Anne Cooper)

Other key strategies include having an updated list of the general heat strategy steps and machine adjustments written down separately to refer to—something most roasters do naturally—and have them somewhere close to the roaster so you can easily grab them when needed. “Download and print your current roast profiles, or have them on a different computer, so you can access the profiles,” says Mike Ebert of Firedancer Coffee Consultants. “Obviously, have them accessible to the roaster itself. Having access to what you need to do will help inform what you might need to do on the roaster.”

And if you still have the ability to read the temperature on the control panel, manually note the temperature every minute so you can still work out the rate of rise on the go, something most roasters said they would worry about not having access to in the event of software failing.

Which reinforces even more the importance of practicing the skill of being able to manually roast, log and calculate on the go without the aid of software, along with knowing how to revert to the control panel if needed. Don’t ignore those control panel readouts just because they don’t match the computer. Always have a backup record of matching temps for the control panel versus the software.

Some other strategies roasters said they implement in case of software failure include:

Always have a spare timer nearby that can be used as soon as a problem with the software is identified.

Have an extra probe installed that is being read elsewhere, independent of the software.

Know how to use/read any analog temperature gauges. Usually these will be reading the environment more than the bean, so knowing how to also roast with the analog environment temperature gauge is a great skill to have.

Have a list of steps/adjustments written down nearby for when the screen completely disappears and/or if you can’t swipe back to the cloud-stored app/profiles.

Have a second computer available that can be used as a backup.

If you can, go to the cloud-stored profiles and double check profile steps/adjustments.

Rely on smell and sound. Practice monitoring/defining the smell at various stages and listening to the resonance of the beans at cracking to help troubleshoot/adjust heat accordingly.

Color check against the same product parameter standards to also make sure the final product is within spec.

Do triangulation tastings to compare with the same product that was roasted with software from start to finish.

Practice for if and when this may happen to you. Actually deliberately try and roast just with time and physical markers to help create muscle memory, so if you do find yourself in a software failing situation, you will ignite your instincts and get yourself out of the roast without any unnecessary panic.

Using visual and aural senses is critical to a roasters’ success. (Photo courtesy of Anne Cooper)

If we don’t practice or have a record of key events/times/phases, we could end up in a scenario of having to throw away a batch of (potentially very expensive) coffee because we didn’t know how to use our senses to get ourselves through the rest of the roast.

In these times of inflation and high prices, we can’t afford to be practicing the very wasteful “burn to learn” philosophy. We need to back ourselves up by writing everything down because you will thank yourself immensely when there is a software failure and you are able to roast your way out of it successfully and calmly, backed up by all your manually recorded information.

Overall, there really is no right or wrong method—manual roasting versus software—just as long as in the event of software failing, we as roasters are fully connected to our baseline profile strategy, which is predominantly about being able to consistently identify and make key physical changes/phases happen at the right time in order to produce the desired end flavor for a specific bean, process and end product.

As Rozental so eloquently summarizes, “All our senses activate, and we look at the color, smell and listen. We might lose a bit of quality, and not be as precise, but at least it’s not a full loss. We are also sometimes positively surprised by the results being better than the software reference. No beans left behind.”

***

Anne Cooper is an Australian roaster who has gained extensive experience in her 29 years in the coffee industry. A former member of the Roasters Guild Executive Council and Education Committee, Anne now works with her training and consulting company, Equilibrium Master Roasters. There, she continues to educate and inspire flame keepers of all levels of experience and develop her extensive roasting skills and knowledge while working on a wide range of roasting machines with small- and large-scale roasting companies, applying various roasting techniques.

Advertisement